Building Construction

Block work / Plaster Work / Painting / Tiles and Marble Installations / Plumbing works

Road Works

Interlock Tiles and Kerb stone Installation/Fabrcation all type of Manholes including Pipeline Installations

Aluminium and Steel Works

Fabrication and Installations of Steel handrails ladders Aluminium door windows kitchen Cabinets Aluminium Cladding etc....

Glass and Mirror Works

Installations of Bathroom Mirrors/ Shower Doors/Glass partitions/ shop front Glass doors with colors and designs

Maintenance Works

Specialized with AC Installations and maintenance repair and Installation of all kind of plumbing works

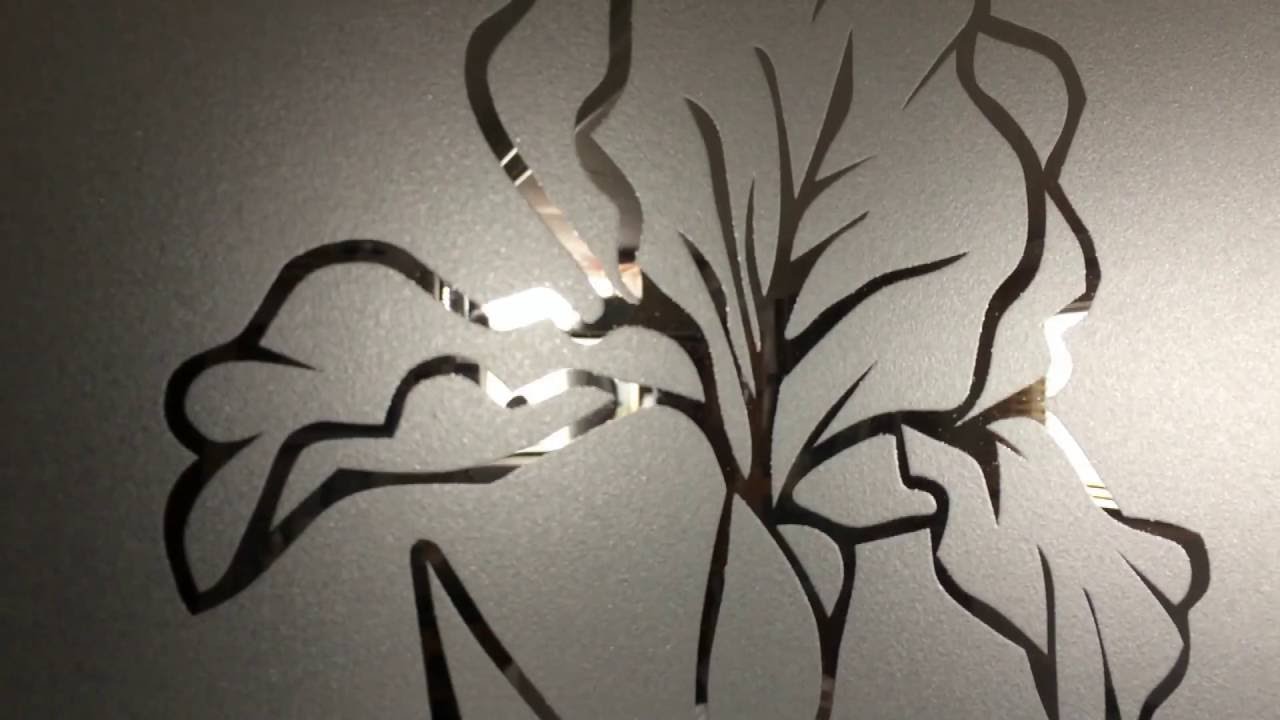

Etching Designs:

Glass etching can add a sense of drama, elegance, and sophistication to otherwise ordinary household items. The contrast of a clear design on a frosted background works well on vases, mirrors, picture frames, and glass storage containers. Etched designs can also be used on windows to provide a decorative privacy screen that still lets in enough light for an airy, open appearance. Monograms, flowers, leaves, and simple geometric shapes are some of the most popular elements in glass etching patterns.

Deep Engraving:

Deep engravers perform a highly specialized deep engraving process resulting in deeper and faster material penetration/removal coupled with ultra-fine details and finishes, which cannot be achieved by mechanical means or by other standard laser systems. Our machines has taken a leadership role in developing deep engraving and has created specialized deep engraving systems along with options and accessories that are ideal for system integrators or end-users.

OUR CAPABILITIES

- PRE-TENDER SERVICES

- PROJECT MANAGEMENT

- ENGINEERING

- MANUFACTURING FACILITIES

- FIELD INSTALLATION

- QUALITY ASSURANCE

- SAFETY

PRE-TENDER SERVICES

- Providing Timely and accurate pricing information.

- Innovative solution for complex Architectural Metal Works.

- Collect and Maintain Project – Specification scope and schedule information

- Attention to unique project needs

PROJECT MANAGEMENT

- Add your content…Our APPROACH is based on key attributes of Trust, Integrity, and Experience.

- Our OBJECTIVE is to create a team approach with Contractors, Consultants, Developers and Engineers to successfully execute projects on time.

- Our STRATEGY is to create warm relations with our Suppliers, Contractors, Consultants and Clients.

- Our PROCEDURE is to create a project specific means and methods plan.

ENGINEERING

- Senior Project Manager providing a key link between Engineers and Operators.

- Ensure full Technical and R&D support from System Producers.

- Ensure the Installed material quality by expertise QA/QC Engineers.

- Competent capability in Design, Engineering, Production Drawing, Execution and Installation.

- Appropriate inspection can assure the accuracy and precision required for the project perfection.

FIELD INSTALLATION

- Periodical In-House training of Employees using new technology.

- Experienced Management personal including Technical team

- Expertise Skilled Labor forces.

- Maintaining on-time Installation at the project timings and complete the work before the deadline.

QUALITY CONTROL

Through built-in monitoring and implementation procedures, Luxury Engineering Construction is committed to delivering a quality construction project and final product. The procedures begin during the pre-construction phase with in-house plan reviews, budgeting and value engineering services, and subcontractor selection. After construction has commenced, quality is achieved through a series of pre-construction conferences for coordinating the various phases of work, monitoring shop drawings and submittals for adherence to plans and specifications, maintaining a clean and safe project site, and employing qualified and competent field supervision. The Quality Control procedures mesh together through a concentrated effort of teamwork involving Luxurys’ Estimators, Project Managers, Safety Director and Field Staff to deliver the Client a successful project.

SAFETY FIRST

At Luxury Engineering Construction, safety is a primary concern. Our full-time Safety staff visits each individual project site, performs regular training and networks with others to insure safe working conditions are being maintained. Weekly safety meetings are held on each project site between the Luxury site staff and subcontractors to stress the importance of jobsite safety and to keep safety in the minds of each individual working on the site. At Luxury Engineering Construction we are always improving.

Repeat client business is our goal, Luxury Engineering Construction commitment to our client does not end with the completion of the project. We strive through our quality control program to minimize warranty needs. However, when warranty issues arise, we have a full-time Warranty Service staff to provide a timely response and follow-up to our clients needs to minimize inconveniences.

MACHINERY AND EQUIPMENTS

We have the “State of the Art” machinery from Japan, Europe & USA in Aluminium & glass processing Industry. Our machinery includes:

- Computerized Double Head Aluminium Cutting Machine

- Section Bending Machine

- Angel Notcher Machine

- Corner Crimping Machine

- Computerized Glass Edge Polish Machine

- Computerized Beveling Machine

- Computerized Etching Machine

- Manual Edge Polish/Bevel Machine